• Converting pressure to electrical signal

4. Original Technical Specifications

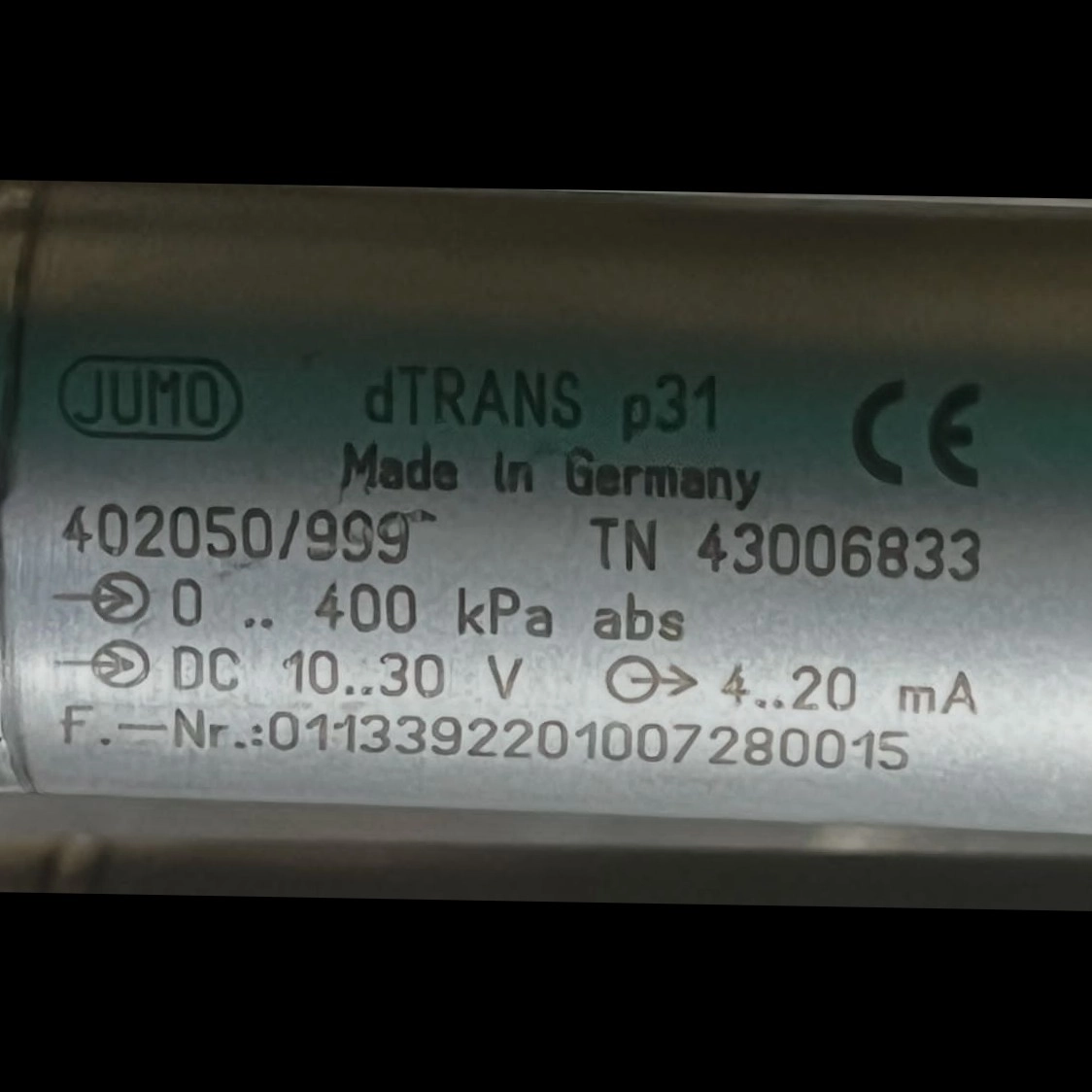

• Pressure range (relastic and Absolute)

• Work temperatures of ambient and fluid

• Type and accuracy of output (eg 4-20 ma)

• Power supply (DC 10-30 V)

• Body and aperture (stainless steel, no extra seals)

5. Mechanical design and process connections

• Types of connections (needle, clamp, din, threads)

• Hygienic Design (Hygienic Design)

6. Benefits and limitations

• Temperature resistance and high pressures

• Long -term durability and stability

• Tips on Use such as Need to Set Calibration

7. Applications and Target Industries

• Food and Pharmaceutical Industries

• Sterilization, Autoclaves

• Chemical, Medical Industries, Water Purification

8. Selecting the right model for specific application

• Choose the appropriate pressure range

• Select the type of connection and body sex based on fluid

• Select the type of output and require a display or converter

9. Installation, maintenance and safety tips

• Installation of correct aperture and for pressure

• Environmental and protective conditions (IP, temperature, vibration)

• Periodic test and calibration

10. Comparison with similar sensors and proposals of alternatives

• Benefits over competitors

• Cost, accuracy, durability

⸻

Technical points and important details of existing sources

Here are some technical information found from different sources:

• This sensor is suitable for fluid temperature in the aperture between approximately -30 and +200 ° C.

• The sensor is produced in a variety of relative pressure and absolute.

• The body and parts that are in contact with the fluid are made of stainless steel and have a "hygienic" design that is suitable for industries with high cleaning.

• Common output: 4-20 MA (dual-wire), but there are also models with voltage output.

• Conservation against water/dust penetration is usually provided at the IP65/IP67 level.